What supply chain disruptions mean for partners and customers

Maintaining a systematized supply chain can ensure product quality, service reliability, and optimal resource capacity. Still, a single disruption can hike costs and drive delays.

Put simply, supply chain disruptions are situations that prevent the steady movement of products from point to point within the supply chain. Imagine disruptions as rocks or pollution that block a river’s water flow. These build-ups can happen over time or all at once.

For disruptions that we’re experiencing, both due to current issues and in the wake of past crises, digitization is our most effective and proactive solution.

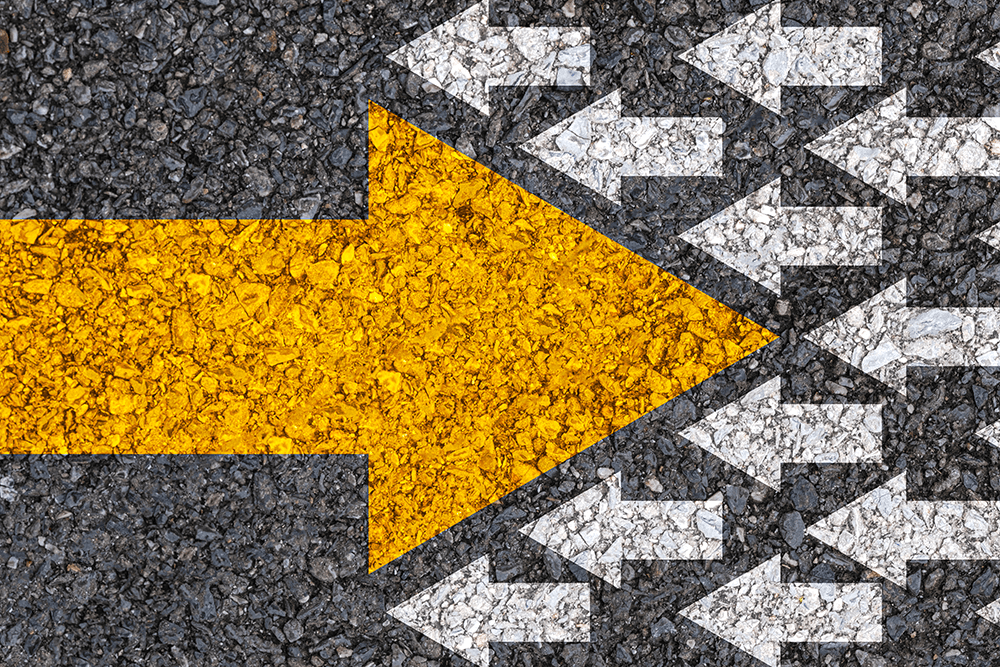

Causes of supply chain disruptions and their impacts

Globally, supply chains have been under pressure since 2019, when vulnerabilities were revealed with drawbacks of items as necessary as toilet paper, and now, baby formula and microchips for cars. Let’s look at some supply chain challenges of the past and present and how companies can future-proof their operations against future unprecedented obstacles.

The effects of COVID-19 on global supply chains

The COVID-19 pandemic continues to disrupt the world—from everyday activities and healthy living to logistics operations—even with global vaccination efforts. The virus created a giant hiccup in the supply chain with factories and ports shut down. Now, with the world’s economy in recovery, why are supply chain issues still happening?

98% of UK businesses blame the pandemic for current supply chain issues.

According to a survey conducted by B2B market research specialist, Coleman Parkes.

For starters, upon their reopening, ports are struggling to meet the customer demand. For example, US consumers spent 40% higher on durables (i.e., air conditioners, washers, dryers, etc.) in October 2021 than in October 2019 and despite expectations of the 2021 holiday market slowing, holiday sales grew 4.1% to a record $886.7 billion. Supply chains were left scrambling with fewer resources and more barriers than ever.

2021 Suez Canal obstruction

The infamous Suez Canal obstruction added to these supply chain barriers, backing up over 376 vessels, including oil tankers and cargo ships. For reference, the Suez Canal was a passage for 12% of global trade in 2020. Mass turmoil arose during the six days in which the canal was blocked, with nearly $10 billion in daily losses.

While consequences for the obstruction haven’t necessarily overflowed into 2022, the occurrence highlighted the vulnerabilities and potential risks involved in freight forwarding.

Brexit

The UK officially announced its exit from Europe in January 2021. This has led to a massive increase in prices for goods and materials, along with delays and shortages in essentials. According to the Parkes survey mentioned above, 86% of UK businesses believe Brexit issues, such as travel restrictions and talent shortages, are to blame for supply chain disruptions. Along with delays, new tariffs, concerning shortages, and other issues, the first 6 months of Brexit saw:

- Timber prices increased by 80%

- Copper and steel prices increased by 40%

- Paints and varnishes have increased by 30%

- Polymers, such as polyethene and polypropylene have increased by 60%

- Timber battens, steel beams, and plastic insulation for roofing have increased by 50%

Current market inflation

According to the Consumer Prices Index (CPI), inflation remained below the UK government’s target of 2% between April 2019 and April 2021 but surpassed in May. Since September 2021, there has been a monthly increase in inflation, reaching a peak 6.2% in March 2022.

While inflation is a result of disruption, it’s also a challenge to global logistics operations. But what is the cause of inflation? Inflation can be a consequence of each of the disruptions we’ve mentioned here that have influenced an imbalance between supply and demand. As the demand for goods has increased, production and supply chains have struggled—a tug-of-war match supply chain leaders who lack operational visibility know well.

Build operational resiliency and prepare against future supply chain disruptions

Automating your supply chain with technology is vital for logistics leaders who intend to balance supply and demand—supply chain crisis or not. Digitalising processes gives your operations an upper hand. It enables visibility into disruptions to help you and your partners make informed decisions based on accurate data and adapt to real-time changes using AI and data-driven solutions. An automated operational workflow empowers complete control over your network from end-to-end.

Quincus’ supply chain solutions are targeted to your industry’s pain points to solve your most pressing logistics challenges.

Future-proof your operations today.

Subscribe to keep up with our latest news